How do you make Custom Jewelry?

Have you been searching for that special piece that you have in mind but you just can’t find what you want in any store or online? Well there’s always an option to get that special piece without settling for what you can find, have that piece custom made! There are a few techniques to make custom jewelry. Depending on what you are imagining, we can make that special piece a few different ways.

You can have it fabricated from prepared metals, such as several different thicknesses of sheet metal, round wire, square or flat wire and many other precasted or forged metal. We take the sketch or ideas described to us and start forming the metals by hand to the shapes desired. This technique works well when making bear claw pendants, shark teeth pendants, bangles, heavy rings and mixed metal pieces.

If want you are envisioning is a little more intricate then something that can be shaped by hand, you can have the piece carved in wax. This technique is done by Master Jeweler, Richard MacPherson. Richard takes the sketch or ideas described to him and starts carving from a block of wax. This is a very delicate process that is truly a work of art. Once the piece is carved to accommodate all stones and the design has been successfully accomplished, it is then casted using the Lost Wax Casting technique.

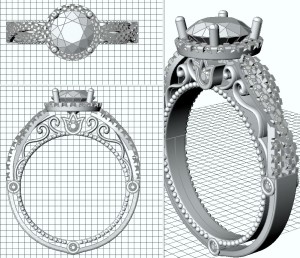

Envisioning something very intricate, something very airy, very unusual? Something that has you scratching your head wondering, “how in the world could anyone make something like that?” Using modern technology, we are able to make the wildest of designs thanks to CAD/CAM software. We can now plug in all the information on stones sizes, metal thicknesses and design of a very intricate piece using technology that was only available to architects in constructing the most unique buildings. Once the piece is designed on a computer using this advanced software, the computer sends the information to a machine that will in turn “grow” the wax. Once the wax is completed we then use the same Lost Wax Casting Technique to turn the piece into metal.

What now? Once the piece has been formed or casted, it just depends on if there are stones or specific finishes needed to accomplish the desired look. If there are no stones, we start the finishing process by filing and polishing to the desired finish. If there are stones, we file and “pre-polish”. What that means is that we polish all metal that will be underneath stones and polish the entire piece about half way finished. This way we will ensure there is no access metal taken off the piece while we handle it to set stones and such. Once we get all stones set, we polish the entire piece to the desired finish.

We hope this helps give you a rough idea of how the process is done and we can explain it more in depth at the time we start designing your piece! Come by and let’s talk about those ideas.